Control Arms Buyer's Guide

Buying a control arm for your car can sometimes be a daunting and confusing task. At maxpeedingrods.com, it is our mission to make that task as an easy and painless as possible. This Buyer's Guide is designed to answer any questions you may have during your search for the right control arms for your car, and how to buy control arms on our website.

What are control arms?

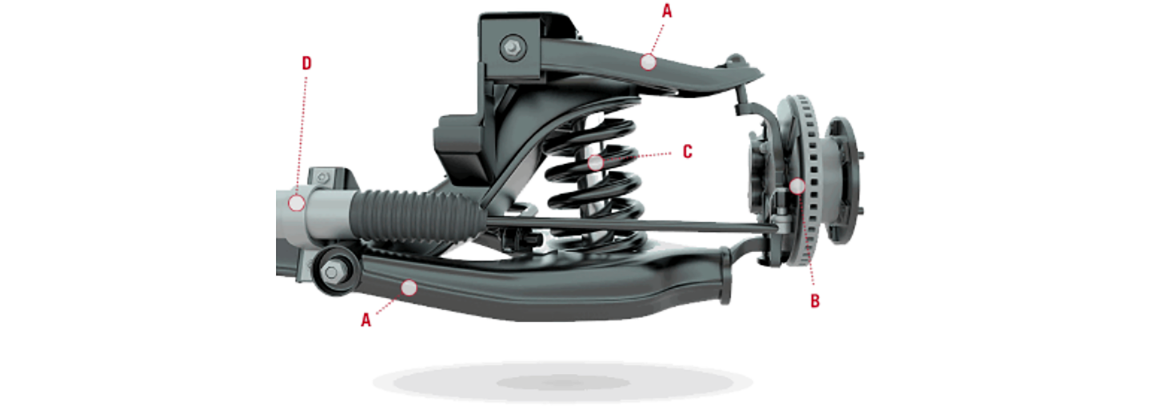

Control arms, sometimes called “A arms,” are the core of your front suspension system. In simple terms, control arms are the link that connects your front wheels to your car. One end connects to the wheel assembly and the other end connects to the framework of your car.

The upper control arm connects to the uppermost area of the front wheel and the lower control arm connects to the lower most area of the front wheel, with both arms then attaching to the frame of the car. If you have independent rear suspension, the design is similar.

The most common types of control arm suspensions are:

• Control arm type suspension

• Strut type suspension

Strut type designs have a lower control arm but no upper control arm. In strut designs, the strut becomes the upper control arm and is sometimes connected directly to the spindle or the lower control arm.

What are the function of control arms?

Control arms may not be common household terms for many vehicle owners. You may have never even heard of it, but it is critical components of your vehicle's suspension system that allow your tires to smoothly go up and down in a controlled fashion. Without it, your ride probably wouldn't be very enjoyable.

Most vehicles use either one or two control arms per wheel, on both the front and rear suspension. Many front-wheel drive vehicles only use a lower control arm, while trucks and SUVs often have both an upper and lower control arm. A control arm connects the wheel hub and steering knuckle to the frame of the vehicle. They are typically equipped with bushings on the frame side of the vehicle and a ball joint on the wheel side of the vehicle that allow flex and controlled movement according to road conditions and steering input from the driver. Control arms allow wheels to move up and down while preventing forward and rearward movement.

How do control arms work?

Each control arm is connected to the vehicle frame with two control arm bushings. These bushings allow the control arms to move up and down.

BThe opposite end of the control arm is attached to a steel spindle. The spindle is what the front wheel is bolted to. On non-strut equipped vehicles, the spindle is attached to both the upper and lower control arms with a ball joint. The ball joint is a steel ball enclosed in a steel socket that allows the spindle and front wheel to rotate left and right and allow the wheels to move up and down following the roads surface.

CSandwiched between the control arm and vehicle frame, positioned in a spring socket, is a heavy steel coil spring that supports the weight of your vehicle and provides a cushion against bumps.

D

To combine the two opposite motions on each end of the control arm, the arms are tied on the frame side to pivot up and down on the control arm bushings. On the opposite end, the control arm is tied to the spindle and front wheel with upper and lower ball joints. The coil spring supports the weight of the car and dampens the shock of road surfaces.

To combine the two opposite motions on each end of the control arm, the arms are tied on the frame side to pivot up and down on the control arm bushings. On the opposite end, the control arm is tied to the spindle and front wheel with upper and lower ball joints. The coil spring supports the weight of the car and dampens the shock of road surfaces.

To ensure that the control arms, bushings and ball joints are in perfect alignment, some control arms include adjustable attachment points at the frame. When necessary, a mechanic can align the front end and keep your car driving straight down the road.

How to choose control arms?

When control arms go bad you’re going to know it. The car may squeak or make a knocking sound, or pull to one side or the other. You also may notice the tires wearing unevenly. This could happen due to normal wear and tear, or the bushing on the control arm may become compromised.

When shopping for your new control arm assembly you’ll want to look for sturdy enough materials at a price within your budget. This part endures quite a bit of stress so you want a durable product.

To make sure you get a good quality control arm assembly, you need to consider the following points:

• Decide on materials. Cast aluminum control arm assemblies are lightweight and corrosion-resistant, however they tend to buckle more easily over rough potholes. Cast iron are exceptionally strong and are typically wishbone-shaped. Stamped steel were typically used on older cars. They’re more inexpensive but can easily fall prey to rust.

• Look for OEM (Original Equipment Manufacturer) -comparable pieces if you’re going with aftermarket parts. High quality aftermarket parts can perform to the same level as OEM parts, just make sure to buy from a reputable seller.

• Choose a control arm assembly that is powder coated or otherwise treated for corrosion resistance.

Why buy coilovers at MaXpeedingRods?

MaXpeedingRods has been engaged in the research of overseas racing products and culture for decades. If you are looking for control arms, you have landed at the right place. On the basis of your vehicle make and model, you can choose from a plethora of automotive maintenance and accessories.

MaXpeedingRods offers a seamless online shopping experience and the streamlined e-commerce interface makes it easy for you to find just the control arms you want.

MaXpeedingRods offers a variety of control arms with high quality.

• 100% brand new in box

• Made by high strength steel durable sprat-paint of Chrome Finish

• Improved suspension geometry to reduce bump steer

• Improved Rear Suspension, Handling. Predictable and even prevents premature Tire Wearing

• Design for Street, Track or Drift Racing Precise Adjustments with Long Service Life

• Perfect for track cars, drift control, street course, off road

• Direct bolt-on for OE factory or replacement

• Professional Installer is highly recommended (no instruction included)

• Alignment Highly Recommended after install

For professional assistance, you can reach out to us via our website https://www.maxpeedingrods.com/

What are the symptoms of a bad or failing control arm?

Over time, the bushings or ball joints on the control arm wear out and can cause all sorts of problems. Usually a problematic control arm assembly will produce a few symptoms that can alert the driver of a potential problem that should be serviced.

1. Steering wheel vibrationOne of the first symptoms commonly associated with bad control arms is steering wheel vibrations. If the bushings or ball joints in the control arm become excessively worn it can cause wheel shimmy, which may cause vibrations that may be felt in the wheel. The vibrations may increase as you accelerate and smoothen out once you are traveling at speed.

2. Steering wanderingAnother symptom commonly associated with bad or failing control arm assembly is steering wandering. Excessively worn ball joints or bushings can cause the vehicle’s steering alignment to shift, which may cause the steering to pull to the left or right when traveling down the road. This will require a constant correction from the driver in order to steer the vehicle straight.

3. Clunking noisesClunking noises are another symptom of possible problems with the control arms on a vehicle. If the bushings or ball joints develop excessive play or looseness, this can cause them to knock during takeoff, or when the vehicle is traveling over rough terrain. The clunking sound will continuously get louder as the component wears or until it eventually breaks. The control arms on a vehicle are very important suspension component, as they are the component that links the spindle, hubs, and therefore wheel to the vehicle’s chassis. When they become worn it can cause problems for the vehicle that may compromise handling, comfort, and safety. For this reason, if you suspect that your vehicle’s control arms may be bad or worn, have the vehicle’s suspension inspected by a professional technician, such as one from YourMechanic. They will be able to replace your control arm assembly if required.

How to install control arms in a car?

If the control arm is damaged due to impact, or if the bushings and/or ball joint need replacement due to wear, it is more time and cost-effective to replace the entire arm as it generally comes complete with new bushings and ball joint.

Part 1: Raise your vehicle Materials Needed

• Floor jack

• Jack stands

• Wheel chocks

Be sure to use a jack and jack stands with the appropriate weight capacity to lift and support your vehicle. If you are unsure of your vehicle’s weight, check the VIN label which is usually located on the inside of the driver’s door or on the door jamb itself for your vehicle’s Gross Vehicle Weight Rating (GVWR).

Step 1: Locate your vehicle’s jacking points.

With most vehicles being low to the ground and having large trays or belly pans under the front of the car, it is best to do one side at a time.

Jack the vehicle up at the recommended jacking points instead of trying to raise it by sliding the jack under the front of the car.

Some vehicles have a clear marker or cut out under the sides of the car located near each wheel to indicate the proper jacking point. If your vehicle does not have these indications, consult your owner's manual for the proper jack point locations. As you are replacing suspension components, it is safer if you do not lift the vehicle from any suspension points.

Step 2: Secure the wheel.

Position the wheel chocks or blocks, in front of and behind at least one or both rear wheels.

Raise the car slowly until the tire just loses contact with the ground.

Once you get to that point, find the lowest point underneath the car at which to place a jack stand.

Be sure to place each jack stand in a strong spot such as under a cross-member or chassis to support the car. Once positioned, slowly lower the car onto the jack stand using the floor jack. Do not fully lower the jack and keep it in the extended position.

Part 2: Replace the control arm Materials Needed

• Ball joint separator tool

• Breaker bar optional

• Hammer

• Ratchet / sockets

• Replacement control arm(s)

• Wrenches - open/box end

Using the ratchet and socket, loosen the lug nuts on the wheel. Carefully remove the wheel and keep it aside.

Step 2: Separate the ball joint from the hub.Select the appropriately sized socket and wrench. The ball joint has a stud that extends into the wheel hub and is secured by a nut and bolt. Remove them.

Step 3: Separate the ball joint.

Insert the ball joint separator between the ball joint and the hub. Give it a tap or two with the hammer.

Don’t worry if it takes a few good whacks to separate them.

Age and mileage sometimes make them difficult to separate.

ball joint removal tool

In some vehicles, you will be able to remove the control arm bolt with a ratchet/socket on one side and a wrench on the other. Others may require you to use two wrenches due to space limitations.

Once you remove the nut and bolt, the control arm should pull out. Use a little muscle to remove it, if needed.

Install the new control arm in the reverse order of removal.

Bolt up the cradle side of the control arm then bolt the ball joint into the hub, making sure to push it in as far as required before tightening the bolt. Reinstall the wheel and lower the vehicle once the control arm is properly secured. Repeat the process on the opposite side, if needed.

Ensure that you have the wheel alignment checked after any suspension repairs. If you are not comfortable with performing this process on your own, get a certified professional, such as one from MaXpeedingRods, to replace the control arm assembly for you.