All related items are made by our own manufacturers. So Maxpeedingrods has the capability to make custom connecting rod, coilovers and crankshaft design to your specification. If you do not find the correct connecting rods, coilovers or crankshaft at our website for your application, please contact us via SalesTH@Maxpeedingrods.com and our Maxpeedingrods Engineers can make custom products built to your exact specifications.

* CONSIDERING THE MANUFACTURER TIME AND COST, THE MINIMUM ORDER QUANTITY IS 12 PIECES

* PRODUCTION CYCLE IS ABOUT 60 DAYS AFTER DRAWING CONFIRMED

* INCLUDING GENUINE ARP 2000 3/8” OR 5/16” BOLTS

* EXTRA COST FOR UPGRADING TO ARP L19 BOLTS

* FORGED SAE 4340 CHROME MOLY STEEL FOR THE HIGHEST STRENGTH AND DURABILITY

* DESIGNED AND PROCESSED BY CNC MACHINE.

* ALL BIG AND SMALL ENDS ARE FINISHED WITH SUNNEN HONING MACHINE

* 100% X*RAYED, SONIC TESTED AND MAGNAFLUXED

* CONSIDERING THE MANUFACTURER TIME AND COST, THE MINIMUM ORDER QUANTITY IS 10 PIECES

* PRODUCTION CYCLE IS ABOUT 180 DAYS AFTER DRAWING CONFIRMED

* PRECISION MANUFACTURED FROM 4340 EN24 AIRCRAFT CHROME MOLY BILLET STEEL

* MINIMAL HEAT TREATMENT DISTORTION

* MINIMAL SIZE CHANGE

* RESISTANCE TO ABRASIONS & BURN CHARACTERISTICS

* SUITED FOR HIGH OUTPUT COMPATIBILITY

* NO REDUCTION IN THE CORES STRENGTH

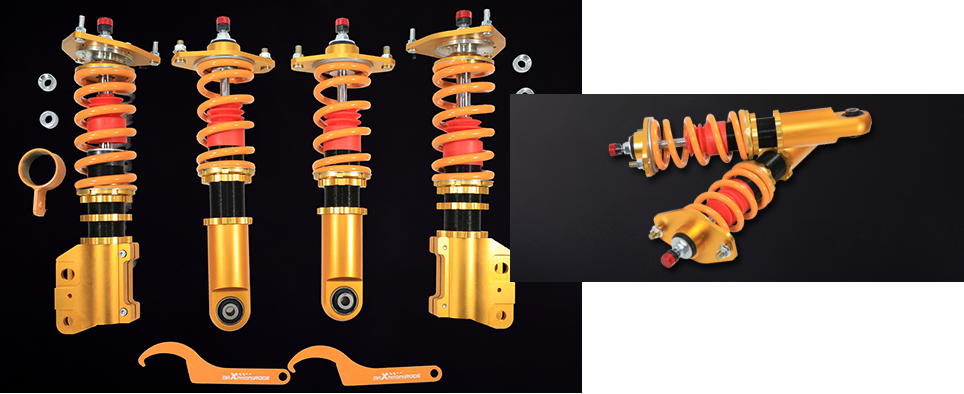

* ADJUSTABLE RIDE HEIGHT

* ADJUSTABLE PRE-LOAD SPRING TENSION

* PILLOW BALL TOP MOUNT -- THIS DESIGN HELPS COMBAT NOISE WHILE TUNING. IT ALSO IMPROVES

THE STEERING FEEL AND RESPONSE

* MOST COMPONENTS ARE MADE FROM 6063 ALUMINUM WITH T6 FOR INCREASED HARDNESS

* HI-TENSILE PERFORMANCE SPRING - UNDER 600,000 TIMES CONTINUOUSLY TEST, THE SPRING DISTORTION

IS LESS THAN 0.04%.

* THE SPECIAL SURFACE TREATMENT IS TO IMPROVE THE DURABILITY AND PERFORMANCE.

* ALL INSERTS COME WITH FITTED RUBBER BOOTS TO PROTECT THE DAMPER AND KEEP CLEAN.

* IDEAL FOR ANY TRACK, DRIFT AND FAST ROAD AND CAN ALSO BE USED FOR DAILY DRIVING.